In the world of machinery, precision is of utmost importance. It’s the difference between a smoothly functioning system and one fraught with problems. Misalignment, even if minor, can lead to significant issues such as increased vibration, premature wear and tear, reduced energy efficiency, and even machine failure. To prevent these problems and ensure your machine operates at its best, using a shaft alignment tool is essential. This specialized equipment enables technicians to align two or more rotating shafts to within a thousandth of an inch.

However, merely having this tool in your arsenal is not enough. Knowing how to use it effectively is crucial. In this comprehensive guide, we will share eight valuable tips to help you get the most from your alignment apparatus.

1. Understand the Basics

Before delving into the alignment process, it’s vital to grasp the basics. Familiarize yourself with different machine components, including bearings, couplings, and, most importantly, the shafts. Understanding how these parts interact will provide you with a solid foundation for successful alignment.

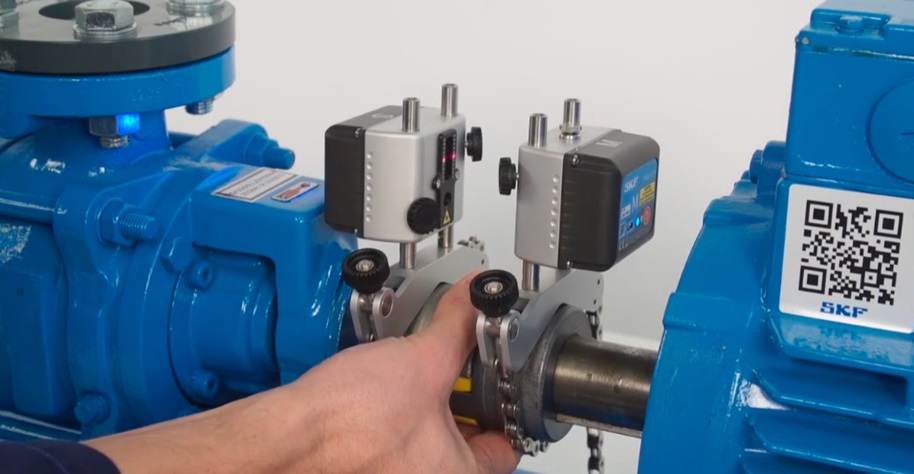

2. Choose the Right Alignment Equipment

The market is flooded with various types of alignment tools, each designed for specific types of machinery or particular alignment tasks. Some are best suited for horizontal shafts, while others excel in vertical shaft alignment. Therefore, understanding your machinery’s specifications and choosing the right tool accordingly is paramount. A well-suited tool not only makes the alignment process smoother but also enhances the accuracy of the results.

3. Cleanliness is Key

The alignment process begins even before you touch the alignment tool. A critical first step is ensuring that all machine components are clean and free from dirt or debris. Even a small amount of grime or rust can impact the accuracy of the alignment, leading to sub-optimal machine performance. So, take the time to clean each part thoroughly before you start.

4. Ensure Proper Installation

After cleaning, the next crucial step is the proper installation of your alignment tool. This step is vital because improper installation can lead to inaccurate results, and in worst-case scenarios, damage to the tool itself. Always follow the manufacturer’s instructions carefully, ensuring each component is correctly placed and securely fastened.

5. Regular Calibration

Calibration is another critical aspect of maintaining the accuracy of your alignment tool. Just like any other precision instrument, the alignment equipment needs regular calibration checks to ensure it’s operating at its best. Refer to the manufacturer’s guidelines for recommended calibration intervals, and stick to them diligently.

6. Perform a ‘Rough’ Alignment First

Before diving into precision alignment, it’s helpful to perform a ‘rough’ alignment first. This process involves manually aligning the shafts as closely as possible by eye or using a straight edge. While this won’t give you perfect alignment, it makes the final precision alignment easier and more accurate by reducing the initial misalignment.

7. Be Patient and Precise

Precision alignment is not a process that should be rushed. Patience is key here. Small adjustments are typically required, and after each one, you should recheck the alignment. It may seem tedious, but this attention to detail will pay off in the long run, resulting in a well-aligned machine that performs optimally.

8. Verify Your Results

Once you’ve completed the alignment process, don’t just pack up your tools and call it a day. Always verify your results. Start the machine and let it run at its operating speed. Monitor for any abnormal vibrations or noise that might indicate misalignment. If everything runs smoothly, then you’ve successfully aligned your shafts.

Conclusion

Proper use of a shaft alignment tool can significantly enhance the performance and lifespan of your machinery. The tips we’ve shared here are not just theoretical suggestions but practical steps that have been proven to work in the field. By following these, you’ll be well on your way to achieving machine precision. Always remember, when it comes to machinery alignment, patience, precision, and the right tools are your best allies.